How to Dimension Timber Accurately using a Planer Thicknesser

This guide explains why a planer thicknesser is an essential tool for accurately sizing timber.

|

How to Dimension Timber Accurately using a Planer Thicknesser

Most woodworkers, whether amateur or professional, will invariably at some point need to use a planer thicknesser. There are various reasons for this:

|

|

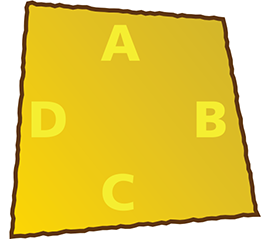

| The Diagram opposite shows an exaggerated cross section of a typical rough-sawn piece of timber which will be used to illustrate the different results that can be achieved using both a standalone thicknesser and a planer thicknesser. |

|

|

How a Thicknesser Works |

|

|

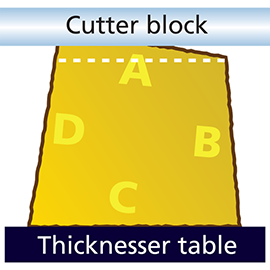

1 |

|

|

|

|

|

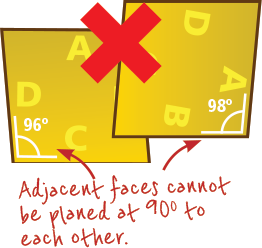

2 Now these opposite faces are parallel, we can see by turning either surface B or D face down on the table that we are only able to plane them parallel to each other but never at 90º to surfaces A or C.

|

|

|

|

|

|

3 It can now be seen that no matter which way the timber is turned, only a parallelogram profile can be achieved. |

|

|

|

|

|

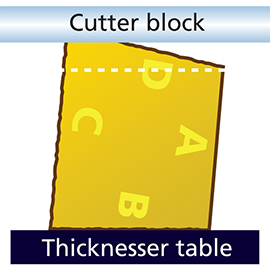

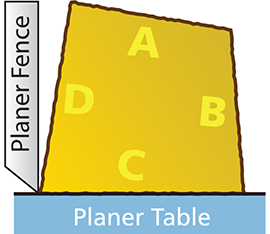

1 Plane surface C to be flat using the machine in the planing mode.

|

|

|

|

|

|

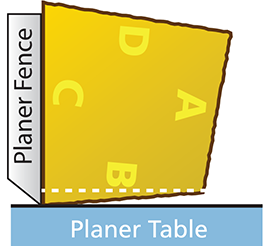

2 Place surface C against the fence, which is set to 90º, and plane surface B until it is at 90º to surface C.

|

|

|

|

|

|

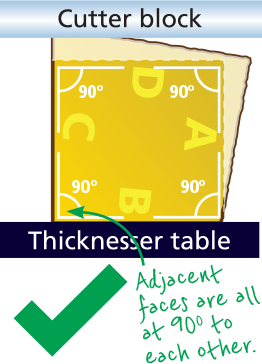

3 Once we have two adjacent faces at 90º to each other, the remaining opposite faces can be thicknessed parallel by using them as a reference.

|

|

.png)