Table Saw Buyer's Guide

With the ability to rip and cross cut solid timber as well as re-sizing sheet material quickly and accurately, a good quality table saw is essential for most keen woodworkers and is likely to be the starting point for many projects.

| With the ability to rip and cross cut solid timber as well as re-sizing sheet material quickly and accurately, a good quality table saw is essential for most keen woodworkers and is likely to be the starting point for many projects. |

|

Choosing the Right Table Saw

Deciding What to Spend

Key Aspects of Table Saw Construction |

|

| Rip Fence & Rails | Mitre Fences and Slots |

|

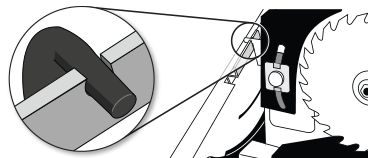

A sturdy, accurate and easily adjustable rip fence is essential for accurate rip cutting. It should also be adjustable to allow precise alignment with the blade and table. It should be possible to set the fence to extend just past the centre of the blade to avoid binding of the timber against the fence which can result in kickback. |

Record Power table saws feature a highly accurate mitre fence system which uses the sliding beam to securely hold and move the mitre fence towards the blade. The traditional method of using a table slot to move the fence is inherently flawed, as the slot itself must be wide enough to allow easy travel, making the mitre fence a loose fit and therefore introducing the potential for inaccuracy. The Record Power system eliminates inaccuracy and table friction and means the fence can be moved close to the blade for maximum support of the timber. |

|

Record Power Rip |

Others’ Rip Fences and Rails Many of our competitors use aluminium extrusions for the fence rail rather than solid steel bars. These provide minimal support and are prone to flexing which greatly reduces accuracy. They are often clamped directly to the table, leaving crude shimming as the only option for adjustment. |

Record Power Mitre

Others’ Mitre |

|

| Sliding Beams and Squaring Frames | Tables |

|

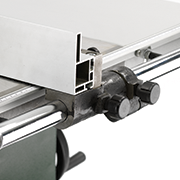

All Record Power table saws feature sliding beams for accurate cross cutting. It is important that beams have good, wide support and be easily adjustable to ensure alignment with the blade. When larger sheets need to be handled regularly, a squaring frame with adequate support is invaluable and makes sizing sheets accurately an easy job. |

The table is the main support and datum for your work so it needs to be smooth, flat and sturdy. Unless you need a portable saw for site use, the ideal material for a table is cast iron which retains its accuracy and provides a solid base for your projects. |

|

Record Power Beams

|

Others’ Beams Some competitors offer beams with poor quality bearings that do not hold their accuracy and provide bumpy action. Adjustments can rely on crude methods such as shimming and access to adjustments can be difficult. |

Record Power Tables |

Others’ Tables Some of our competitors offer tables that look like cast iron but are in fact cast aluminium which is simply not as robust or strong. Those that do offer cast iron tables often omit the expensive and time consuming process of surface grinding, resulting in an inferior table surface. Ensure that any extension tables provide adequate rigidity and accuracy – Foldaway or quick change tables may look appealing but it is very difficult to offer these features without compromises in the rigidity of the extension and poor surface alignment. |

| Blade Rise, Fall and Tilt | Weight |

|

To use a table saw safely, accurately and to its full capacity it is important to be able to adjust the height and angle of the blade quickly and easily. |

Weight of construction is important as it is with any machine. The heavier the machine, the more stable it is when in use and the less it will be affected by vibration. Weight also provides a good indication of the quality of components used during manufacture. Unless you need a portable machine for site-use, a heavy machine is better for supporting large sheets and heavy timbers. |

|

Record Power Rise, |

Others’ Rise, Fall and Tilt |

|

|

Internal Construction and Trunnions |

|

It is critical for the motor and saw unit to have rigid support - Only with sufficient support can the blade be accurately and securely positioned. |

|

Record Power Internal Construction and Trunnions

|

Others’ Internal Construction and Trunnions

|

.png)

.png)